About ConDoor

ConDoor Door Solutions is a leading producer of insulated overhead doors for commercial and residential buildings. The company has three production sites in The Netherlands and Hungary, where 175 employees work daily on the development of tailor-made sustainable doors — translating the wishes of their customers into high-quality products.

The challenge

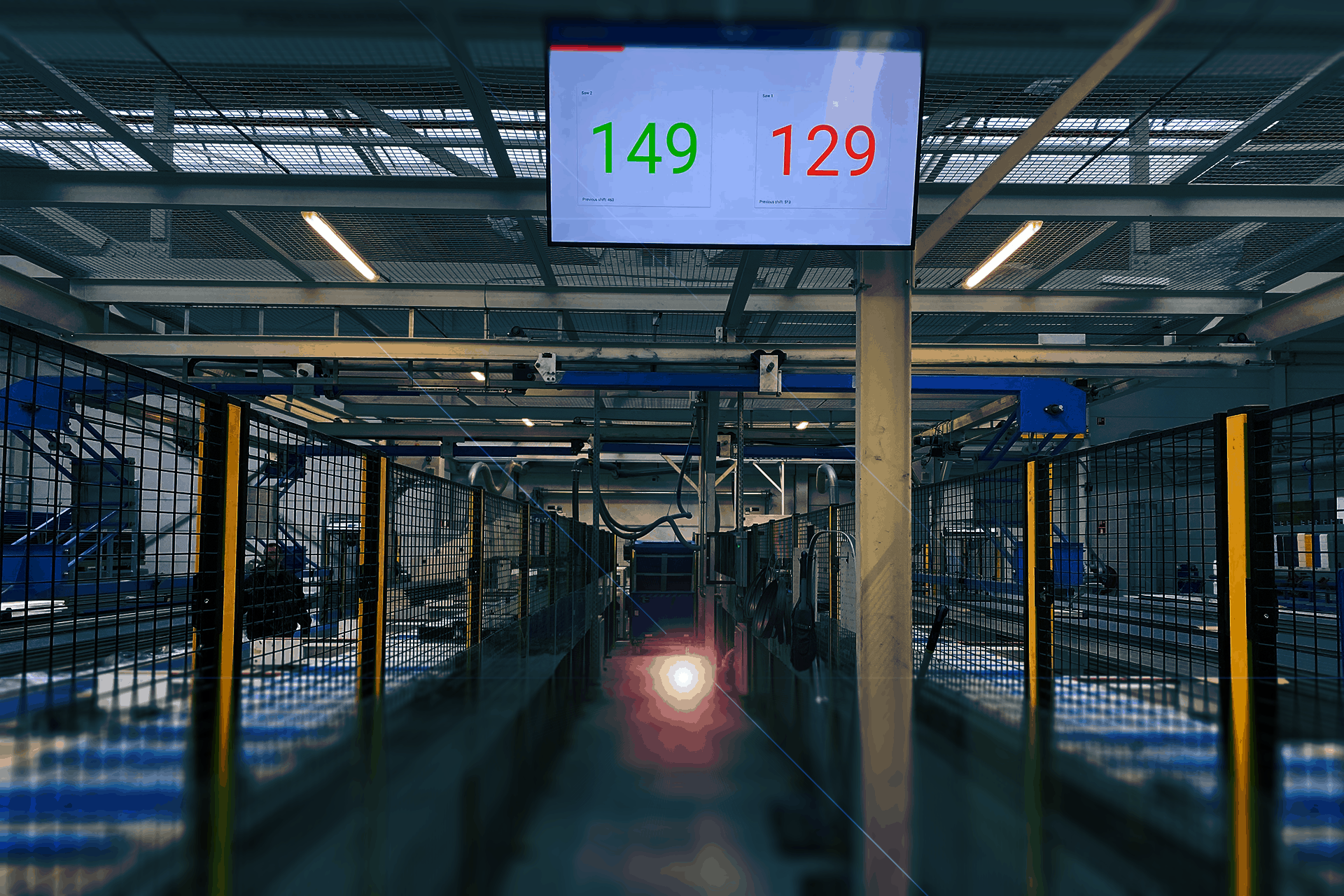

Due to the growing demand for residential and industrial doors, ConDoor increased its production with twenty percent each year. To keep up with this trend, the ConDoor team was looking into ways to realize maximum production rates with their current product line and wanting to upgrade their current manufacturing process while keeping daily production going. The Synadia team was challenged to think of a smart solution that could reduce downtime to a minimum — creating a future proof and flexible production line where innovations can be implemented easily.

Our approach

To understand the ConDoor’s goals and way of working, the Synadia team kicked off this project with hands-on workshops with ConDoor employees. Together we took a step back to be able to analyze the current situation. We created a clear overview of their status quo and pinpointing areas of improvement. The outcome of these sessions was used to define a long term roadmap. This roadmap focussed on technical improvements as well as project management issues that need to be handled.

The Synadia team guided ConDoor during the process of implementation, helping the ConDoor team to schedule and implement software updates in such a way that production could keep going, and downtime could be reduced. Synadia simultaneously advised on software improvements that needed to be implemented to increase the stability of the production line. To reduce the risk of downtime, a support team of specialists was set up. This team is on stand by 15 hours a day, in case any errors would occur that could impact production rates. All errors and corresponding solutions were logged, creating a knowledge base for ConDoor operators. If similar issues appear in the future, operators know exactly how to solve them.

Deliverables

By combining new and improved software with a more efficient innovation workflow, Synadia and ConDoor were able to create a stable, sustainable, and future proof manufacturing process. Condoor is now ready to expand its production without the risk of unplanned downtime easily.

Analysis of status quo

Long term innovation roadmap

Flexible optimization workflow

Stable and sustainable software

Stand-by support team

Discover the ConDoor functionalities created by Synadia

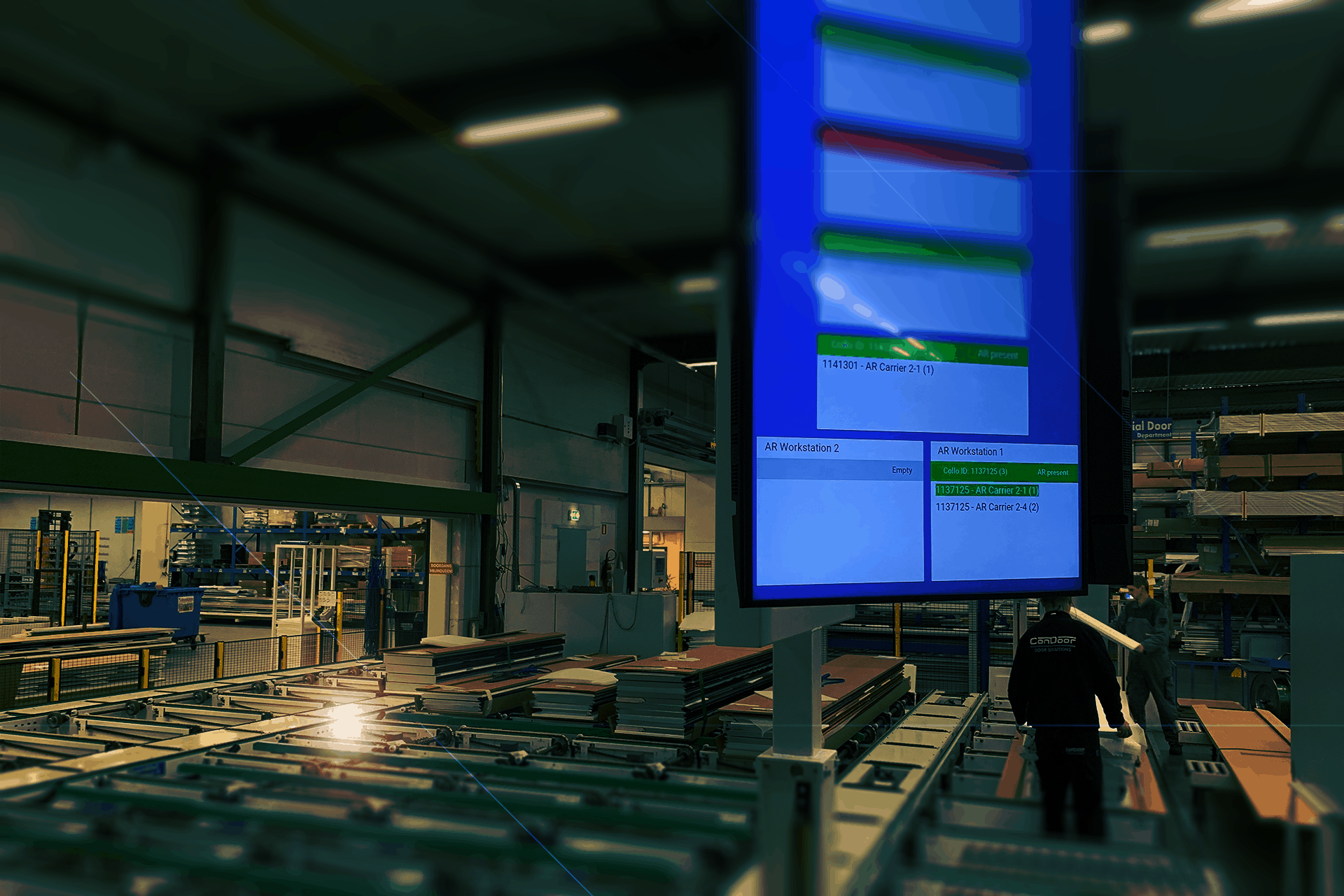

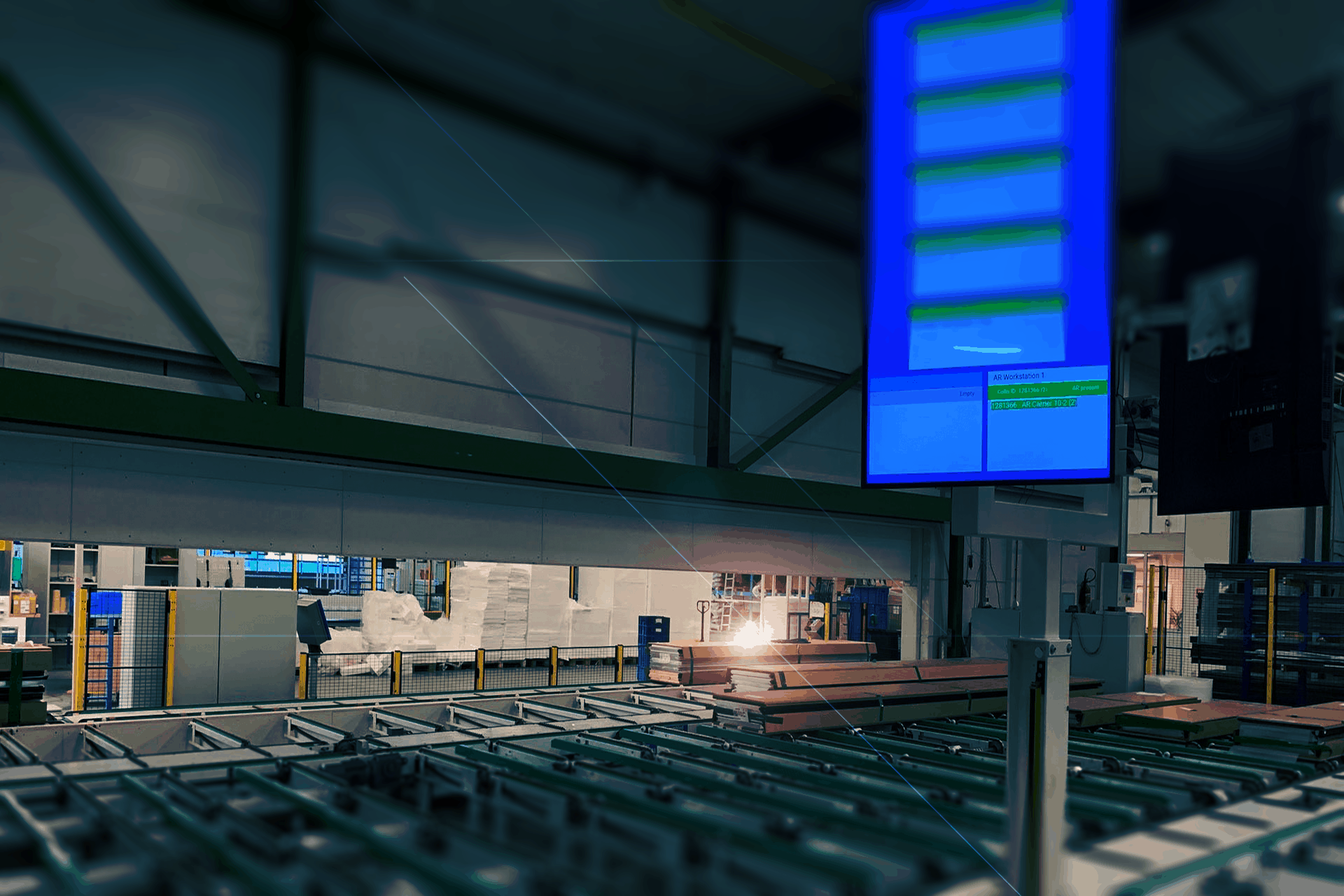

A custom app to lower production lead time

To make life easier for the ConDoor operators, Synadia also created a tailor-made track & trace app. This app runs on an android phone, which is placed in a Cognex scanner. This app helps operators smoothen the picking process by quickly locating production parts. Once the product has been traced, the operator scans the parts to keep track of stock. Every step of the process is scanned & confirmed, facing out any mistakes.

The cool thing is, this device is also connected to the actual machine! It can send and receive instructions directly to the correct station, so no additional user interactions are needed. When the operator finished the scan process at the handheld, the door is automatically send to the next station and the a new door is already on his way.

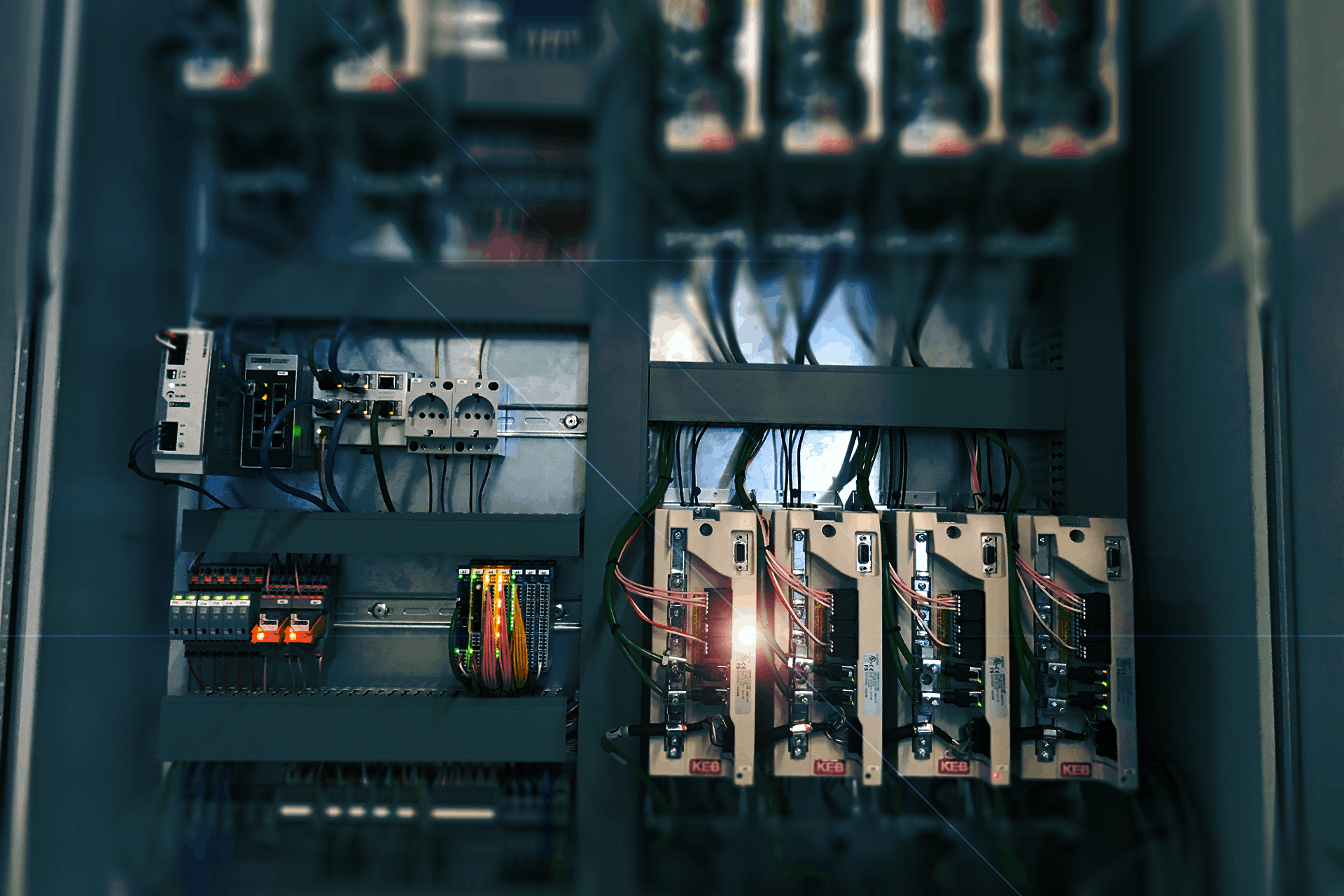

Automatic order processing with PLC software

Automatic order processing with PLC software

The Synadia team equipped several machines with new programmable logic controller (PLC) software. By linking this software to the ERP system at ConDoor, orders are automatically processed without the assistance of an operator.

The main advantage is that operator costs can be reduced and different types of doors can be produced at the same time. Meaning that ConDoor can automatically process all sorts of orders via one production line.