About ConDoor

ConDoor Door Solutions is a leading manufacturer of insulated overhead doors for commercial and residential buildings. With three production facilities in the Netherlands and Hungary, ConDoor focus on crafting high-quality, made-to-order doors that meet the specific needs of their customers. Their commitment to customization and sustainability drives a continuous search for smarter, more reliable production processes, making operational excellence a daily priority.

The challenge

Driven by a growing demand for residential and industrial doors, ConDoor has been scaling up production by 20% annually. To keep pace without disrupting daily operations, the team needed to boost output on their existing product line while modernizing the manufacturing process. They turned to Synadia to develop a smart, future-proof solution, one that would minimize unplanned downtime, support continuous improvement, and allow new innovations to be implemented without halting production..

Our approach

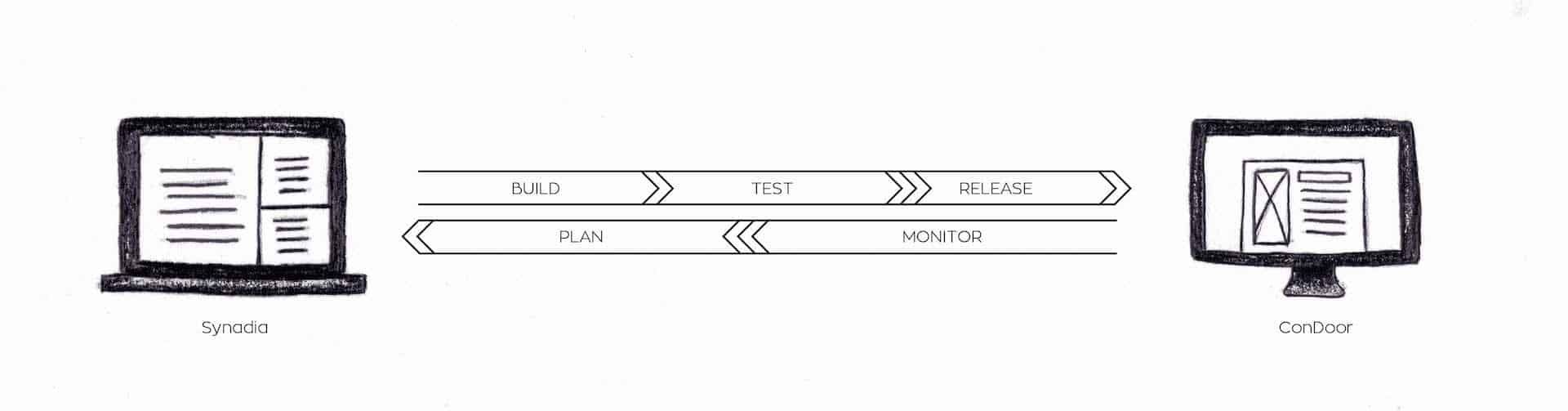

To gain a deep understanding of ConDoor’s operations and ambitions, the Synadia team started with hands-on workshops involving employees from across the production floor. Together, we took a step back to analyze the current situation and identify pain points. These sessions resulted in a clear, shared overview of the status quo and revealed key areas for improvement. Based on these insights, we defined a long-term roadmap, addressing both technical upgrades and project management challenges to ensure sustainable progress.

Synadia guided ConDoor through the entire implementation process, ensuring that software updates were rolled out without interrupting daily production. By carefully planning deployments and minimizing risk, downtime was significantly reduced. In parallel, Synadia advised on critical software improvements to enhance the stability of the production line.

To further safeguard operations, a dedicated support team was established—available 15 hours a day to respond swiftly to any production-impacting issues. Every error and its resolution were meticulously logged, creating a living knowledge base for ConDoor operators. This ensures that recurring issues can be solved quickly and independently, keeping production on track.

Deliverables

By combining robust new software with a streamlined innovation workflow, Synadia and ConDoor established a stable, scalable, and future-proof manufacturing process. ConDoor is now fully equipped to scale production, without the risk of unplanned downtime.

Real-time quality monitoring integrated into existing production lines

Structured innovation workflow enabling continuous improvements

Minimized unplanned downtime through smarter software and support

Knowledge base for operators to resolve recurring issues instantly

Scalable and future-proof production setup ready for 20% annual growth

Our App use case

Zero Errors, Maximum Flow: Smart App Integration Boosts Efficiency to 70%

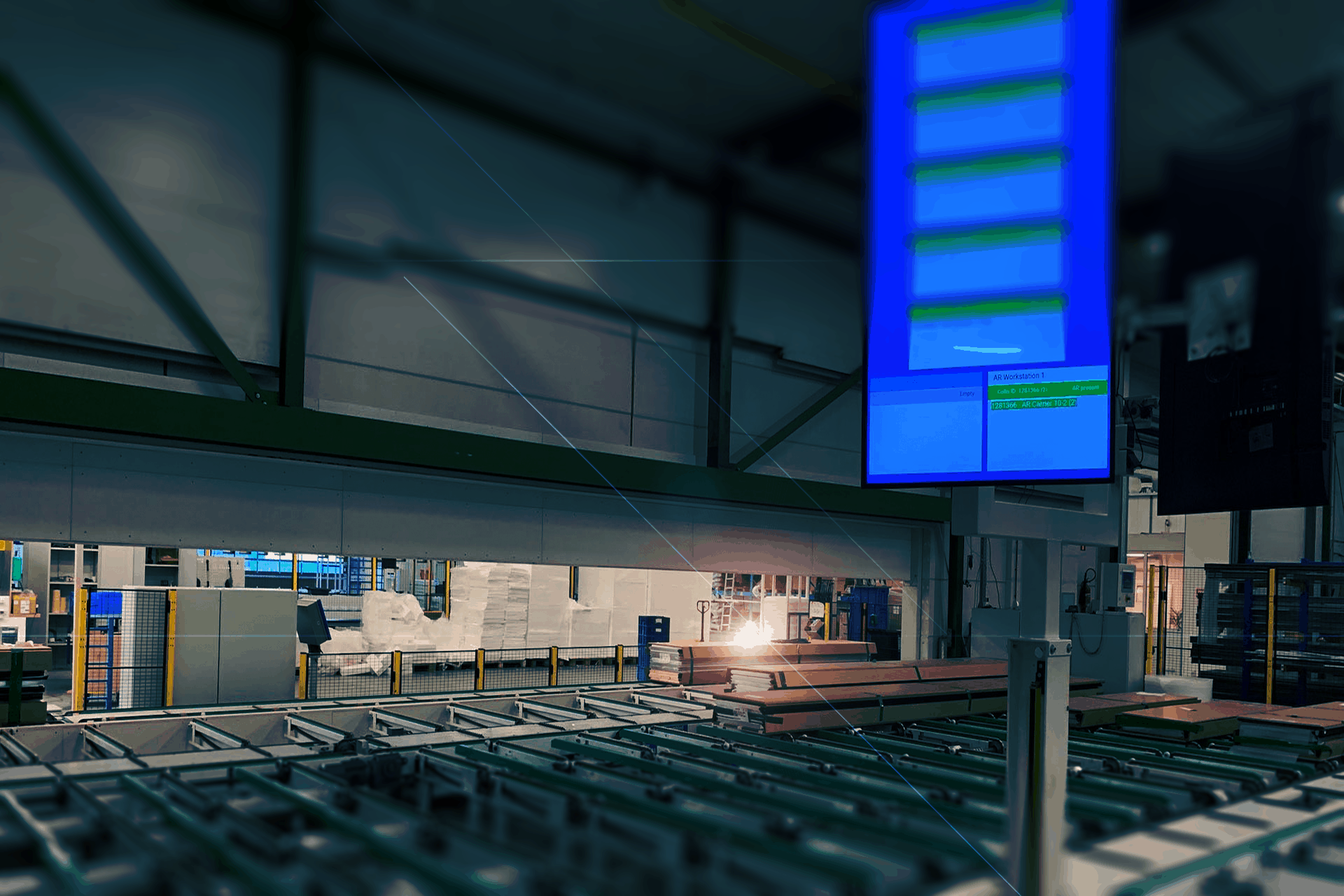

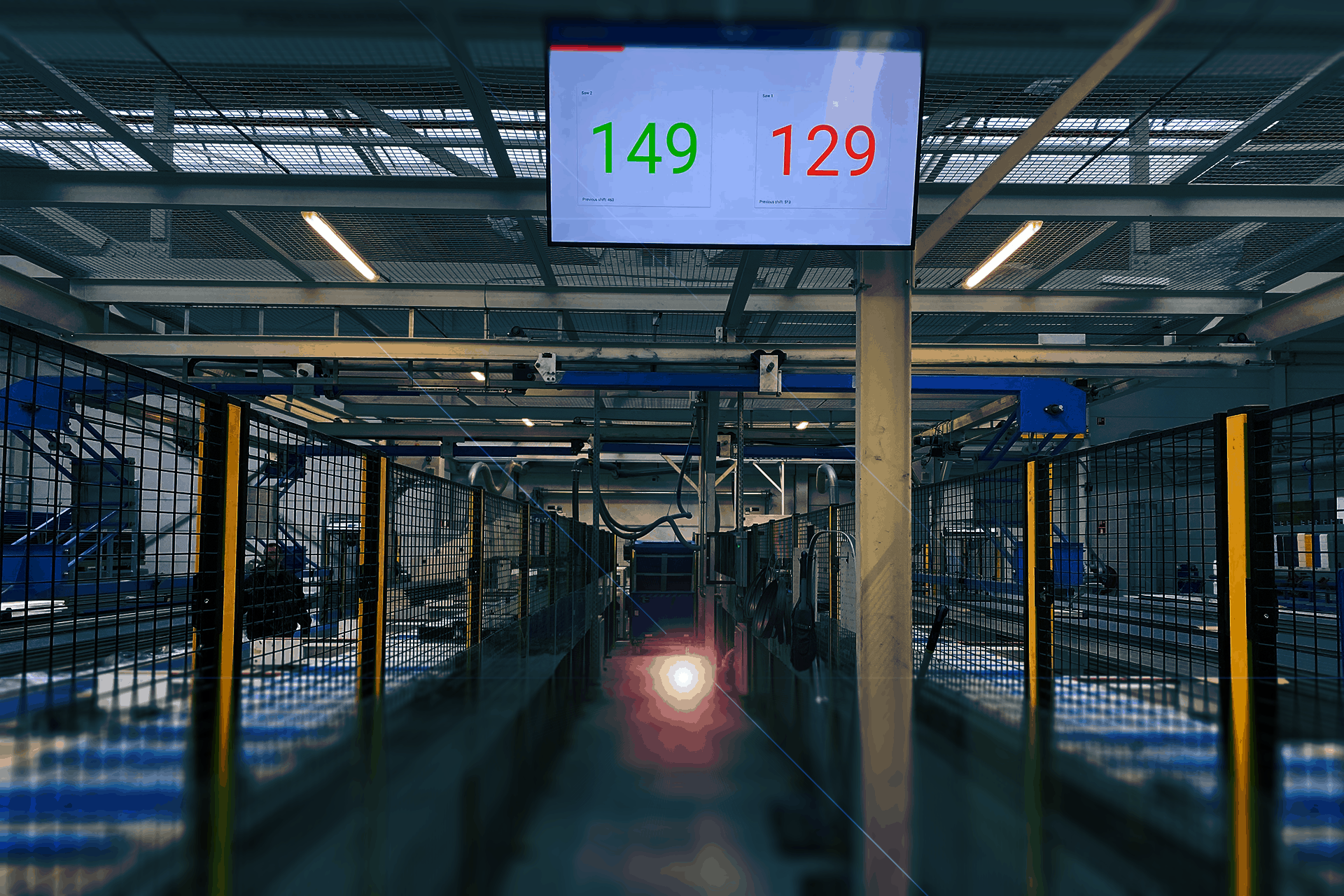

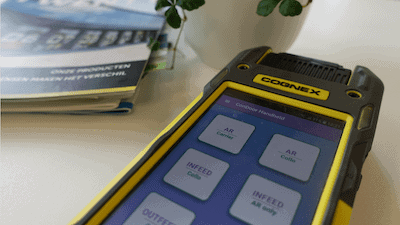

To further optimize production efficiency, Synadia developed a custom app fully integrated into ConDoor’s MES solution. This app guides operators in collecting external accessories linked to each order and ensures they are delivered to the right place at the right time, directly within the active production flow.

Every step in the process is verified by scanning, eliminating errors such as attaching the wrong components. Combined with real-time dashboards positioned along the production line, this solution has enabled ConDoor to reach an impressive 70% efficiency rate, keeping the line running smoothly without unnecessary interruptions.

Automatic order processing with PLC software

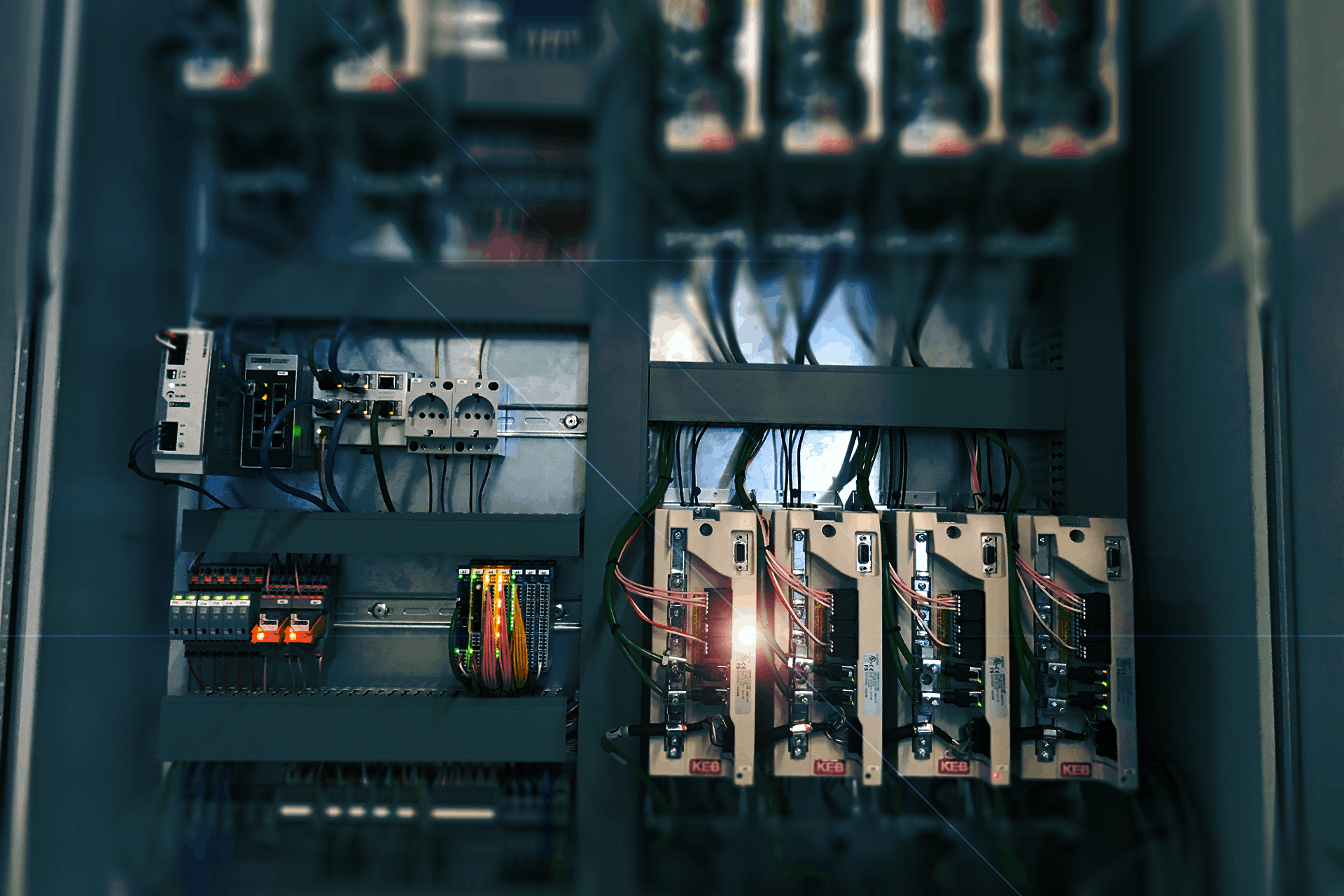

To support ConDoor’s highly flexible, order-driven production process, where every product requires different machine settings. Synadia fully integrated the PLC into the MES system. We established real-time communication with the Sigmatek PLCs by developing a custom MQTT library, enabling seamless data exchange between machines and the MES.

This setup allows order information to be sent directly from the MES to the PLC, dynamically adjusting machine settings per product without manual intervention. It ensures each door is manufactured with the exact specifications required, without delays, misconfigurations, or rework. This transforms high-mix production into a streamlined, dependable, and future-ready process.

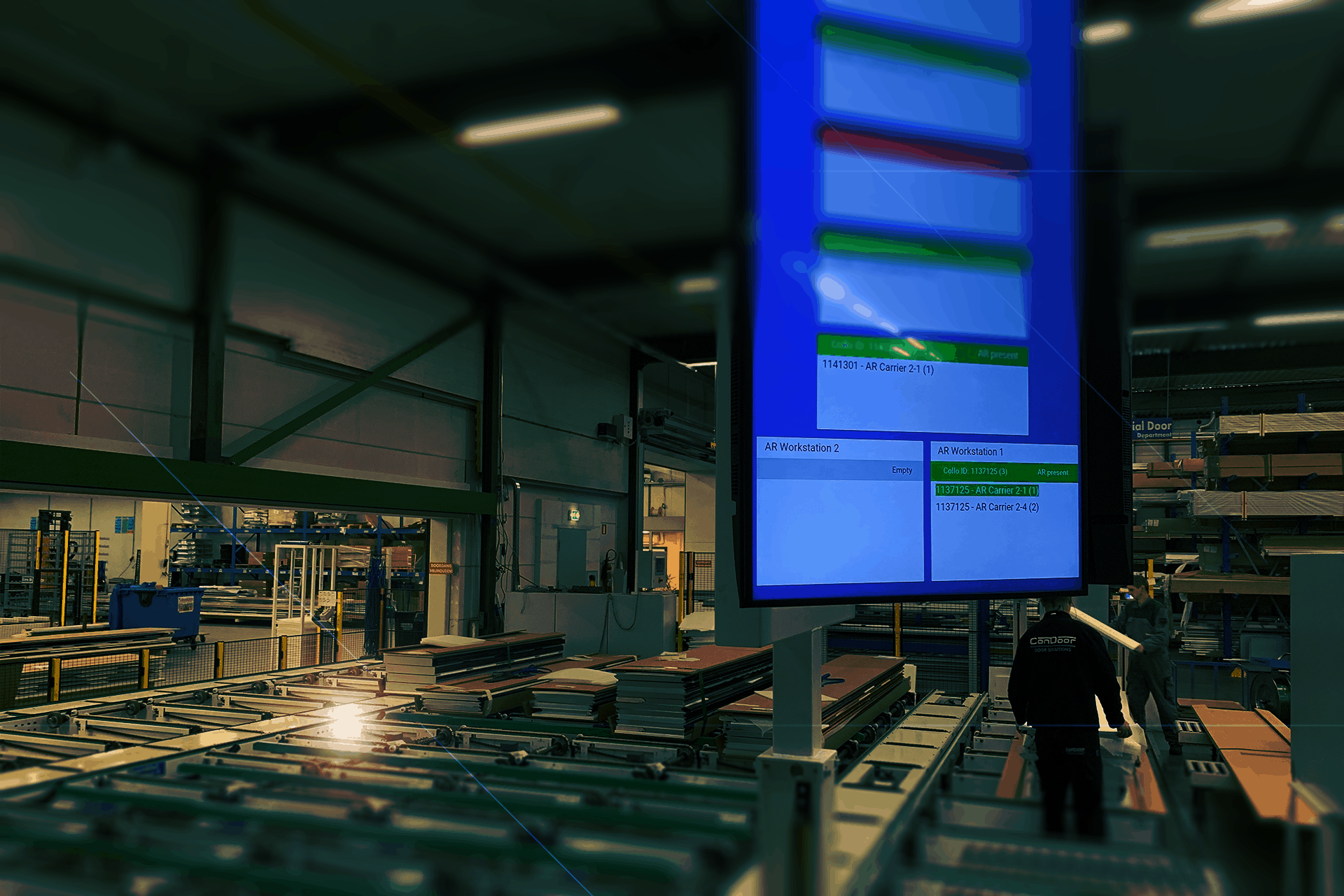

Order picking

To further support ConDoor’s order-specific production approach, Synadia developed and implemented a smart order picking app. This app ensures that semi-finished components are picked and assembled precisely according to the specifications of each individual order.

The app is fully integrated with the MES system and connected directly to machines on the shop floor. As soon as an order is released, the app guides operators through the picking process and triggers machine configurations accordingly, ensuring that all semi-finished parts are produced with the right settings, at the right time, for the right product.

This integration eliminates manual errors, reduces delays, and guarantees that every product moves through the line with maximum accuracy and efficiency.