About Glaesum Group

The Glaesum Group a the holding that is focussing in heat, metal and process technology. The holding covers three individual companies that each cover their own expertise. In 2019 the group decided to invest in the Kelvin TTX. A state-of-the-art console for temperature management, thermotherapy and body slimming applications.

The Kelvin TTX is completely managed from the cloud. A perfect example of a solution that is designed to scale up easily when sales increase and still be able to control and improve your product line remotely“

Remi van Wijngaarden

Commercial Director Synadia

Discover the Kelvin TTX functionalities created by Synadia

Kelvin TTX

The Kelvin TTX had to work faster, easier and more precise. Impossible? Not for us! We changed the software to custom-made and the Kelvin TTX did what our client wanted.

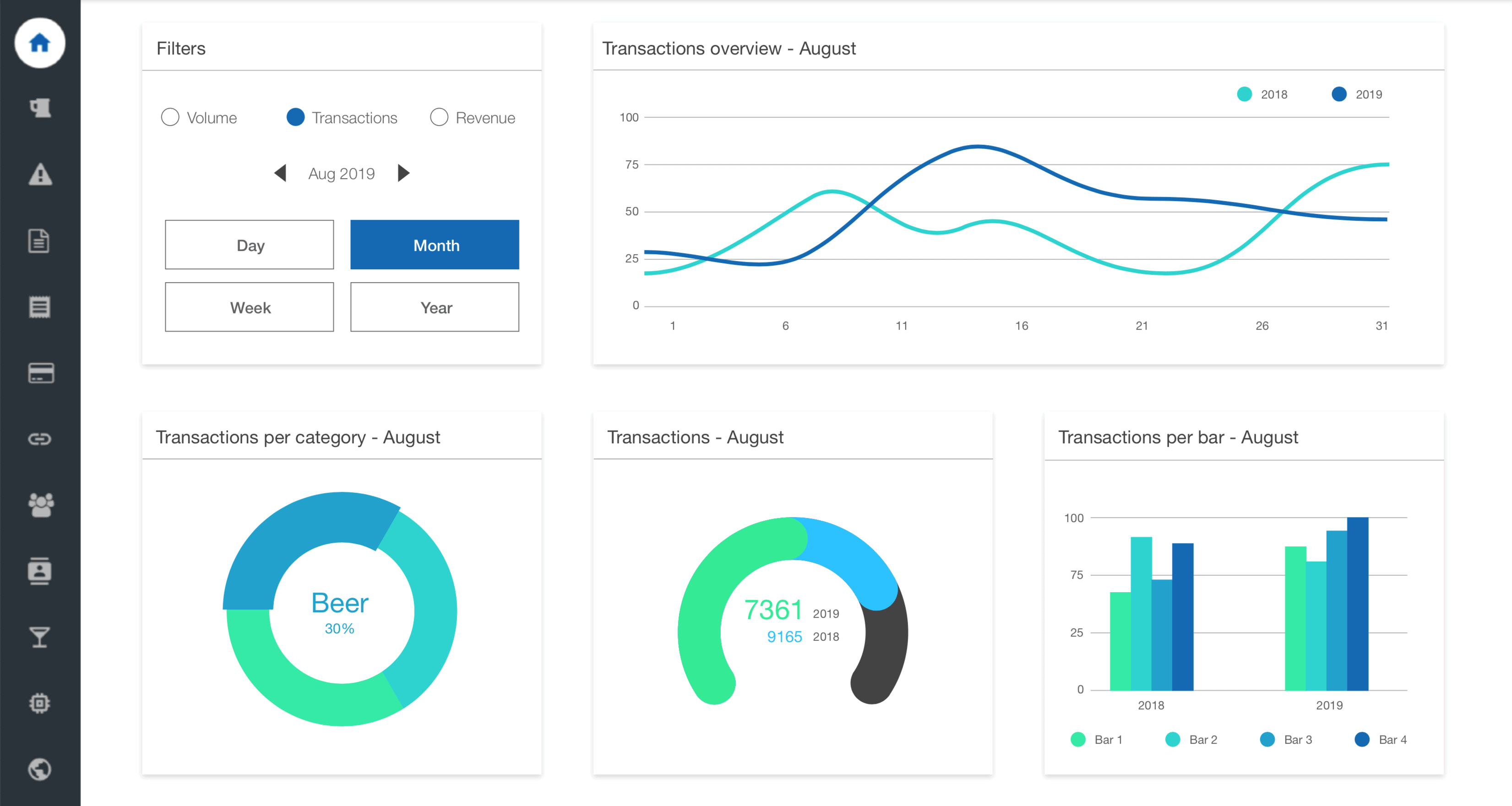

WHAT OUR CLIENT WANTED

What if a device’s standard software doesn’t do what you want? In that case, you immediately ask the Synadia explorers to create the impossible, custom-made software and to make the device even smarter than it already is. This is wat our client of the Kelvin TTX asked us and we made possible.

OUR SOLUTION

We made the Kelvin TTX custom-made and smart! The console has 0.1 degrees water temperature control accuracy, a fast changeover from hot to cold in 45 seconds and an easy setup and closed-loop water management. The specifications of the Kelvin TTX are:

About Kelvin TTX

Kelvin TTX is a state-of-the-art console that provides full range temperature control. It is the number one choice for patient temperature management, thermotherapy and body slimming applications.

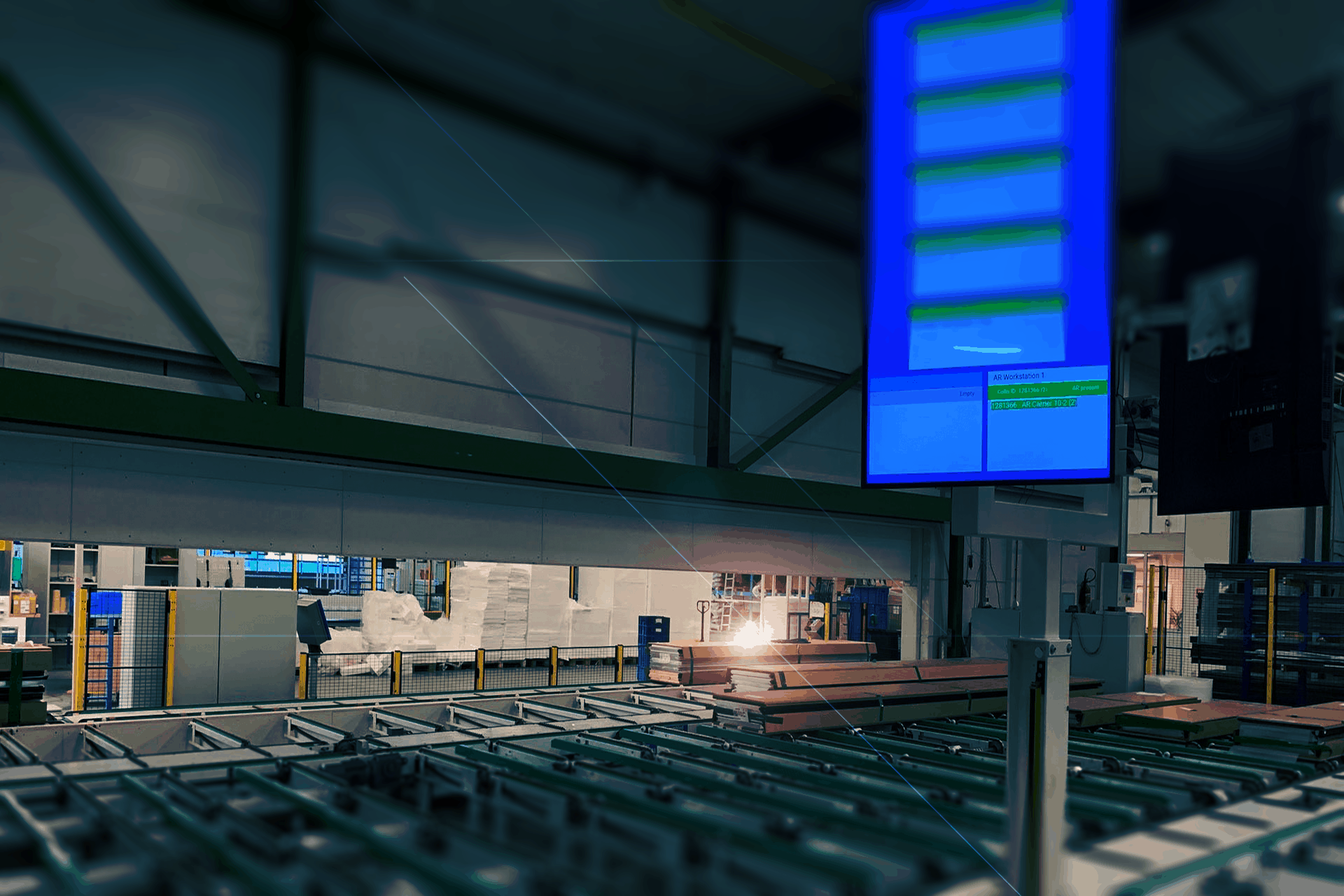

System configuration

In this configuration, we have efficiently re-arranged the processes and cleverly linked them to the different devices. This makes the system even more efficient and smarter.