Unlocking Scalable IT-OT Integration Through IoT: Synadia’s Approach

How do you seamlessly connect two worlds, IT and OT, in today’s industry? At Synadia, we have a clear answer: IoT technology! We see every device, big or small, as an IoT device, and it’s that perspective that makes all the difference. With our innovative approach, we bring IT and OT together in a scalable and efficient way that truly makes an impact.

A Smart Approach to Every Device

At Synadia, we see potential for intelligence in every device. From small temperature sensors to massive industrial machines, we treat them all as part of the IoT ecosystem. By utilizing standardized IoT technology, we streamline the connection process for any device type, ensuring a consistent, secure, and scalable approach. Through powerful cloud platforms like AWS—where, as an official partner, we tap into over 200 services—our solutions are designed for global scalability. This setup lets us focus entirely on functionality, allowing us to develop up to four times faster than traditional methods. The result? A genuinely cloud-native SaaS solution that transforms the way businesses operate.

The challenges of IT and OT Integration

For many companies, the OT world remains a mystery, and bridging it with IT is an even greater challenge. Intervening in production processes carries substantial risk—one wrong move can lead to costly consequences. Synadia brings a rare blend of expertise: deep knowledge of scalable cloud software combined with an in-depth understanding of PLCs (Programmable Logic Controllers). This unique combination allows us to seamlessly integrate IT and OT using cloud technology, ensuring secure, reliable, and risk-free connectivity that unlocks the full potential of industrial operations.

Case study

A Fully Digitalized Factory

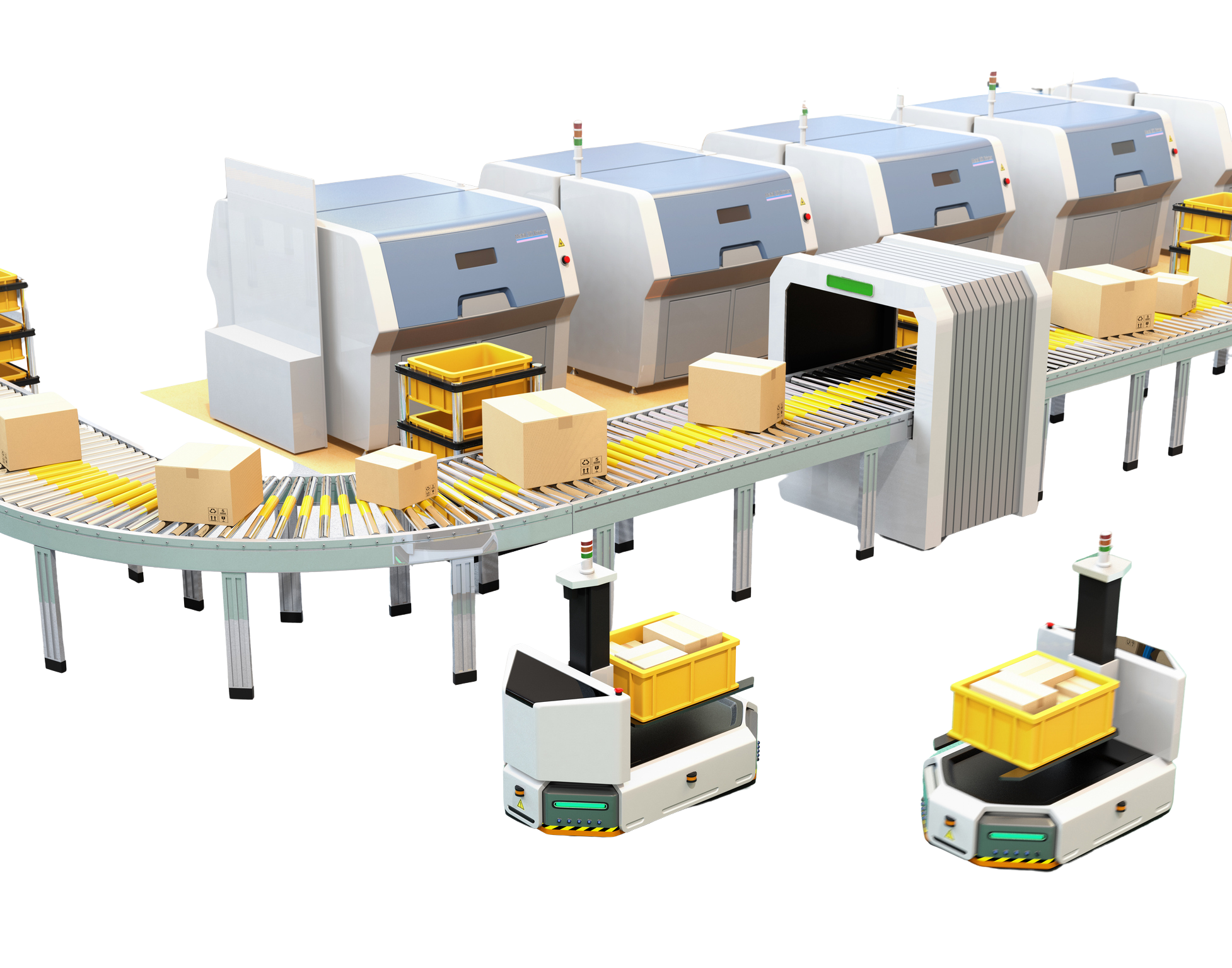

One of our proudest projects (and a true tech marvel!) was building a cloud-based MES (Manufacturing Execution System) for a factory that we completely digitalized within a year. Picture this: over 20 machines in a single production line, all humming together, with orders automatically scheduled based on delivery deadlines. Each order—unique in its own quirky way—came with over 50 different components, which added a bit of a puzzle.

With RFID technology, we tracked each order in real time as it journeyed through production. This wasn’t just for the thrill of watching things move; it let us feed real-time data directly to the machines, telling each exactly what needed to be done. Every machine knew precisely how to cut, mill, and shape the products—thanks to a single digital platform calling the shots.

And we didn’t stop there. We threw in a massive buffering system, 50 meters long and 15 meters high, that could temporarily hold over 1,000 products, all managed by cloud software. Once prepped, the products glided through an automated powder coating line before reaching assembly, where operators received clear instructions via an app. It’s factory magic, fully connected and orchestrated by the cloud!

Benefits

With our approach, customers no longer have to depend on a few specialists holding all the secrets to their production lines. Errors? Practically a thing of the past! Orders are sent digitally straight to the machines, and operators receive crystal-clear instructions on what to do next. Plus, our automated system juggles countless parameters behind the scenes, optimizing order schedules and fine-tuning processes. The result? A smooth-running operation that’s more efficient than ever, leaving everyone to breathe a little easier and focus on what truly matters.

About Synadia

At Synadia in Amsterdam, we specialize in connecting technology to the cloud, bringing data flows and process control to the digital age. From mechanical engineering to food, pharmaceuticals, and logistics, we make complex processes easier, smarter, and faster. As an Amazon Consulting Partner and official AWS IoT SiteWise Edge partner, we’re at the cutting edge of on-site data collection and processing. With AWS power behind us, we’re driving digital transformation across industries, one cloud-based solution at a time!

The Technology behind our solution

At Synadia, we’ve embraced cloud-native solutions with a fully serverless, event-driven architecture that keeps costs low and systems flexible. By linking IT and OT through the MQTT protocol in a JSON format, we can adapt data seamlessly without needing to synchronize updates across every software component.

For asset management, we rely on AWS SiteWise, giving us real-time insights into machine data and allowing us to calculate OEE (Overall Equipment Effectiveness) on the spot. In this setup, every device communicates directly with our cloud software, which not only keeps things running smoothly but also dramatically speeds up time-to-market.

Security and scalability

At Synadia, security isn’t just a checkbox; it’s a core principle. Every connection between machines and cloud software is locked down with certificates, and we keep a close eye on data streams with continuous monitoring. Thanks to serverless, event-driven technology, our platform scales both horizontally and vertically with no limits, keeping up with even the largest demands. Plus, we’ve built the system to effortlessly connect multiple factories, creating a seamless network of smart, secure production sites.

The future of IT and OT integration at Synadia

Our vision is simple yet powerful: by building fully cloud-native solutions, we ensure our customers stay ahead and future-proof. By leveraging the cloud to its fullest, we scale as if we’re a team of hundreds. Looking ahead, we’ll offer SaaS solutions that bring real-time tracking and data analysis, enabling complete digitalization of processes tailored to customer needs—all without needing a single line of code from programmers.

With our expertise and fresh approach, Synadia is poised to bridge the gap between IT and OT, taking the industry to new heights.