Industry 4.0 is about data, not just machines

Industry 4.0 is often associated with smart factories, robotics, and advanced automation. But the real shift is not in hardware. It is in how data is processed, shared, and used across the entire operational landscape.

When production data stays locked inside PLCs or local systems, improvement remains limited. When that data becomes accessible, structured, and connected through the cloud, organizations gain the ability to understand and improve operations continuously.

Industry 4.0 is therefore not a machine upgrade. It is an architectural shift.

Why automation alone does not create intelligence

Traditional industrial systems were designed to control machines reliably. They were not designed to share data across factories, integrate with enterprise systems, or support real-time analytics.

As a result, many organizations have highly automated processes but limited visibility into how those processes perform as a whole. Decisions are still based on fragmented information instead of a unified operational view.

Industry 4.0 requires moving beyond isolated automation toward connected intelligence.

Where industrial intelligence actually happens

The cloud enables industrial organizations to aggregate data across assets, sites, and systems, creating a shared operational foundation. It allows models, analytics, and applications to evolve continuously without disrupting production environments.

Instead of embedding complexity into machines, intelligence can be structured in a scalable environment that supports real-time monitoring, predictive analysis, and cross-factory optimisation.

This shift allows factories to evolve from automated environments into learning systems.

How Synadia enables Industry 4.0 in practice

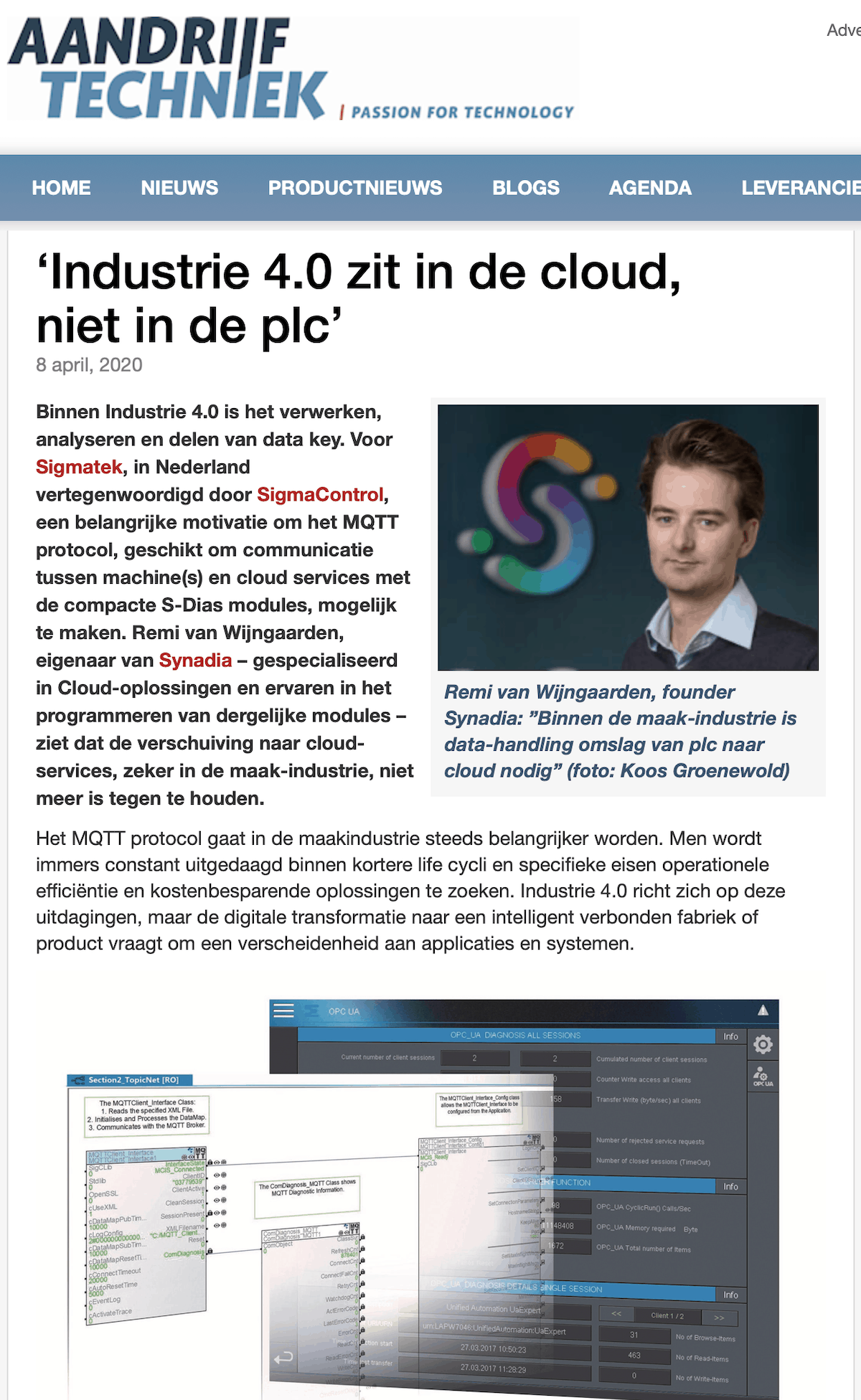

At Synadia, we help industrial organizations move from machine-centric automation toward cloud-connected operational intelligence. Our platforms connect PLCs, sensors, and industrial systems to structured data environments where insight, analysis, and improvement can scale across sites.

By combining OT expertise with cloud-native development, we create architectures where factories remain reliable locally while intelligence grows centrally.

Industry 4.0 is not about replacing machines. It is about connecting them into an environment that understands what they are doing.

The future of industry is connected intelligence

Factories that treat data as a core operational asset can improve faster, respond earlier, and scale improvements across locations. Industry 4.0 becomes real when information flows freely between machines, people, and systems.