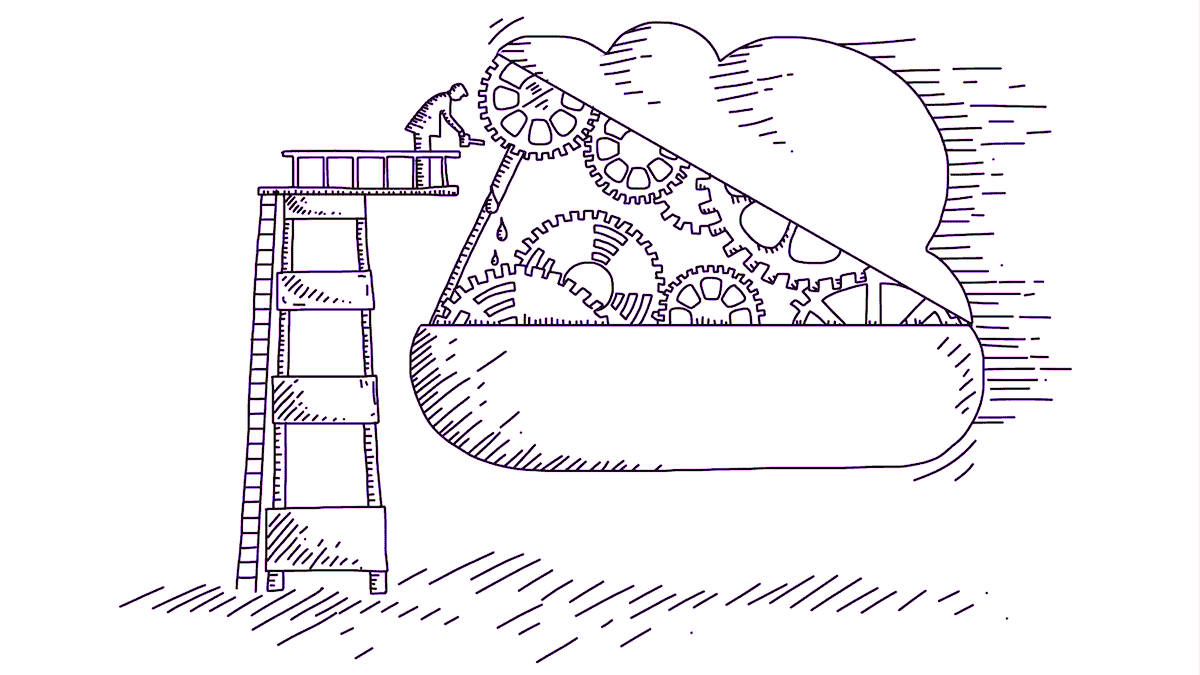

What if an operator in the factory no longer has to manually check a machine or discover an error? Does that sound impossible? All this information will be shown via the cloud so you can use the machine to the max. Our team makes it possible!

Current situation

For various companies, we ensure that machines do what we want and preferably that the machines make the overall process run much better. We change it into smart software with the result that the factory will become a smart factory. Our client is able to collect big data and make processes run more efficiently.

Secured MQTT connection

We collect the information from the PLC’s via a fully secured MQTT connection (Message Queue Telemetry Transport). Originally MQTT was used in Telemetry. With this secured connection all collected data can be sent from the machines to the cloud via a TLS certificate. TLS ensures that the data that is sent between the PLC and the cloud is encrypted and made unreadable.

How we make the impossible?

We are still fully engaged in this project. The link between the PLC’s and the cloud has been finished and the architecture has been determined. By mapping the architecture, we know which data from the PLCs we want to collect in the cloud. For the employees in the factory, we clearly arrange this data in a specially designed portal.