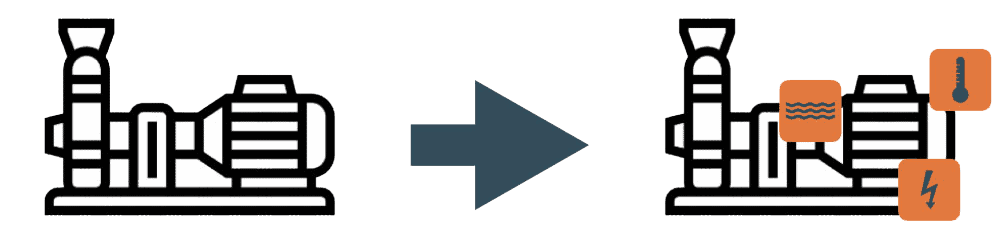

Reduce downtime and plan maintenance

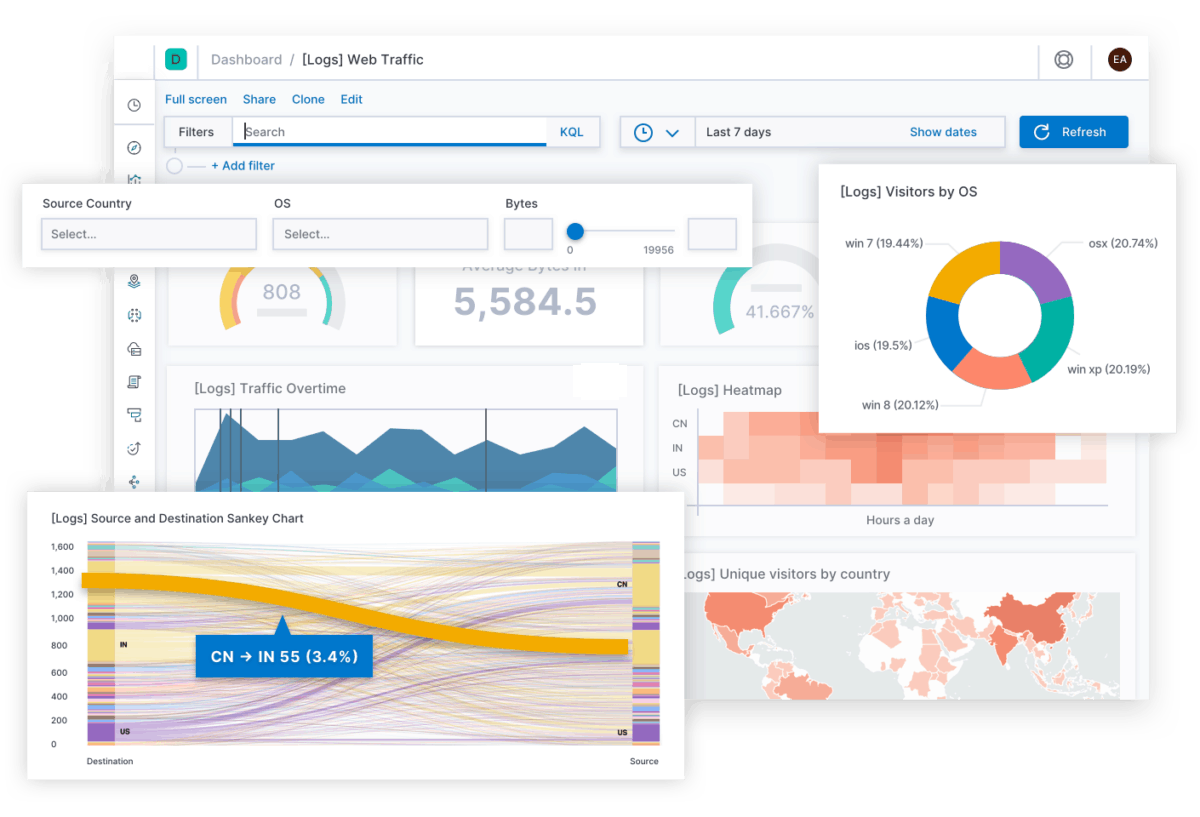

By adding extra digital eyes and hands to your machine, we start monitoring your solution 24/7. When something else happing, than usually, we send you a notification, and with real-time dashboards, you can see the actual state.

Plan your maintenance before your machine breaks down and reduce your downtime and safe costs.

Why connect your machinepark to the #cloud?